Endress+Hauser

Cement industry faces both fluctuating raw material prices and complex customer demands. These challenges make optimizing production processes more crucial than ever. Energy costs, particularly in the clinker production process, can account for 65% to 75% of total variable costs. Therefore, accurate process data obtained with reliable instruments is key to reducing costs without compromising product quality.

Endress+Hauser industry consultants, together with their customers, have achieved remarkable results and improved plant optimization while maintaining a high level of operational safety in numerous industrial sectors, including precious metals, cement, and steel production. This success is driven not only by their technical expertise and industry-optimized product portfolio, but also by their business conviction. They believe in building long-term relationships with their customers, not just short-term profits.

• 70+ years of experience in measurement technologies.

• More than 10 million devices installed worldwide.

• And more than 150,000 smart level sensors used in cement silos worldwide.

Cement production consists of many complex stages:

• Raw material preparation

• Clinker production (kiln)

• Cooling and storage

• Grinding and final product

Each stage is critical for both quality and cost. Therefore, using accurate measurement and control systems at every step is essential to increase efficiency.

Monitoring of Raw Material and Clinker Silos

In order to keep production going it is necessary to continuously monitor stock levels in the raw meal and clinker silos. As storage vessels come in many shapes and sizes, level monitoring can be a challenge.

Endress+Hauser offers a variety of level monitoring technologies and solutions designed for challenging environments such as dust and abrasion.

• 80 Ghz radar level sensor is best suited for measurements in high silos or bunkers.

• A capacitance point level rope probe is used to prevent overflow of bunkers for raw material

• A vibration level switch you can help you to avoid overspills in clinker silos.

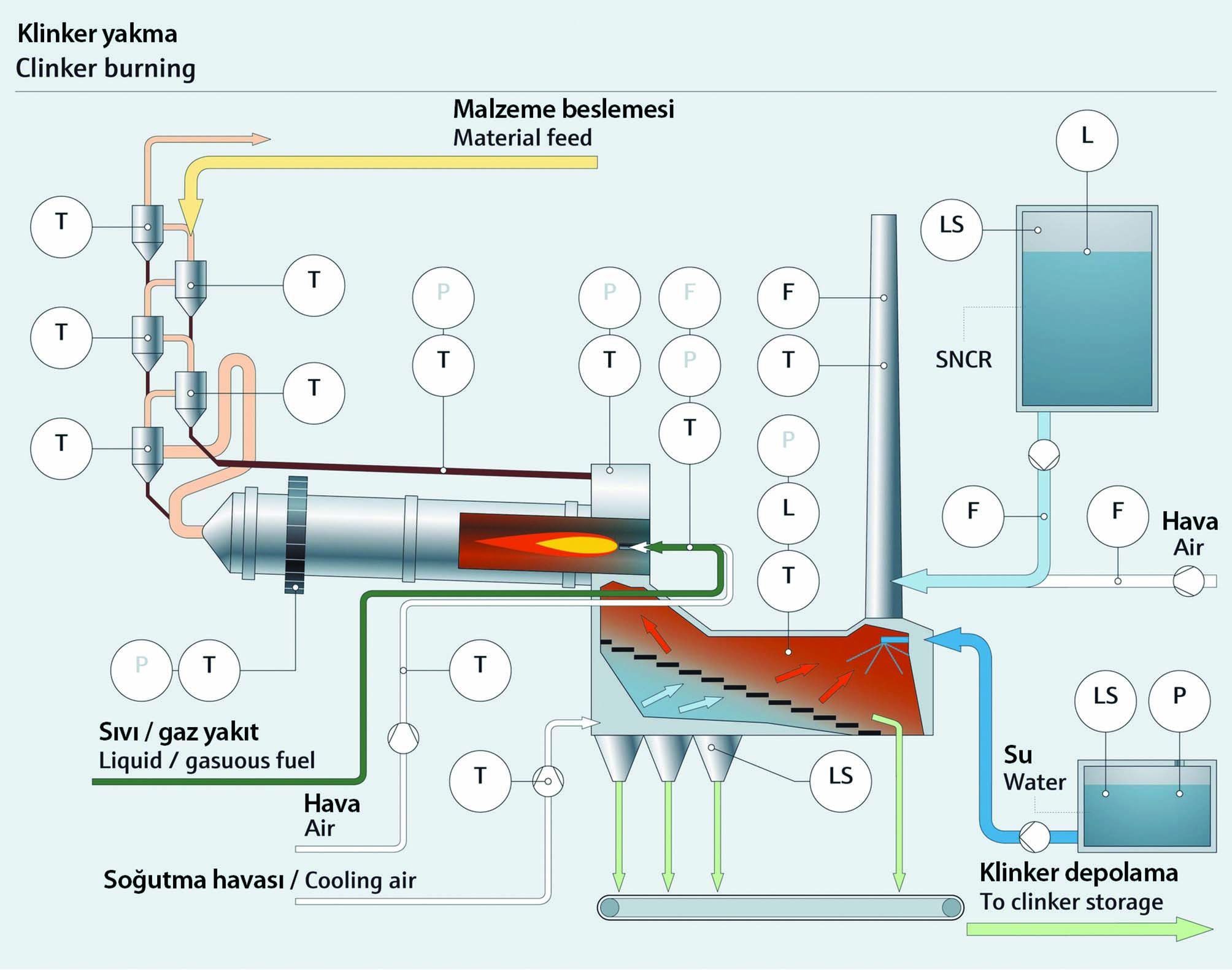

Kiln Burner Control and Fuel Oil Dosing

Pyroprocessing is generally regarded as the heart of cement production. It is the stage in which most of the operating costs of cement manufacturing appear, and is also therefore the area where most of the opportunities for process improvement exist. The main parameter for these processes is naturally temperature. By monitoring it, you can ensure a consistent product quality and optimize fuel consumption.

• For temperature measurement in the upper cyclones of the preheater, use a thermocouple with an advanced ceramic thermowell made of silicon nitride.

• For the bottom cyclones, we recommend thermometers with a bar stock thermowell made from a nickel cobalt which offers unparalleled resistance against aggressive gases.

• Coriolis flowmeters optimize the burner by regulating the mass flow of oil to the burner and provide the oil heating system with online temperature and viscosity measurements.

Clinker cooler monitoring

The clinker cooler is one of the most critical applications in cement production as the rate of cooling can be critical to the clinker quality and overall performance of cement. Thanks to its comprehensive portfolio, Endress+Hauser offers a complete clinker cooler monitoring package from a single source. This includes:

• Differential pressure sensors for metering and monitoring cooling air consumption

• Flow meters for air cooling and high temperature radar level sensors for clinker bed height monitoring to regulate cooler grate speed and air volumes

• Non-intrusive blockage sensors for material collection silos under the clinker cooler grate

• Non-invasive radiometric scale for mass flow on clinker screw conveyors or belt feeders

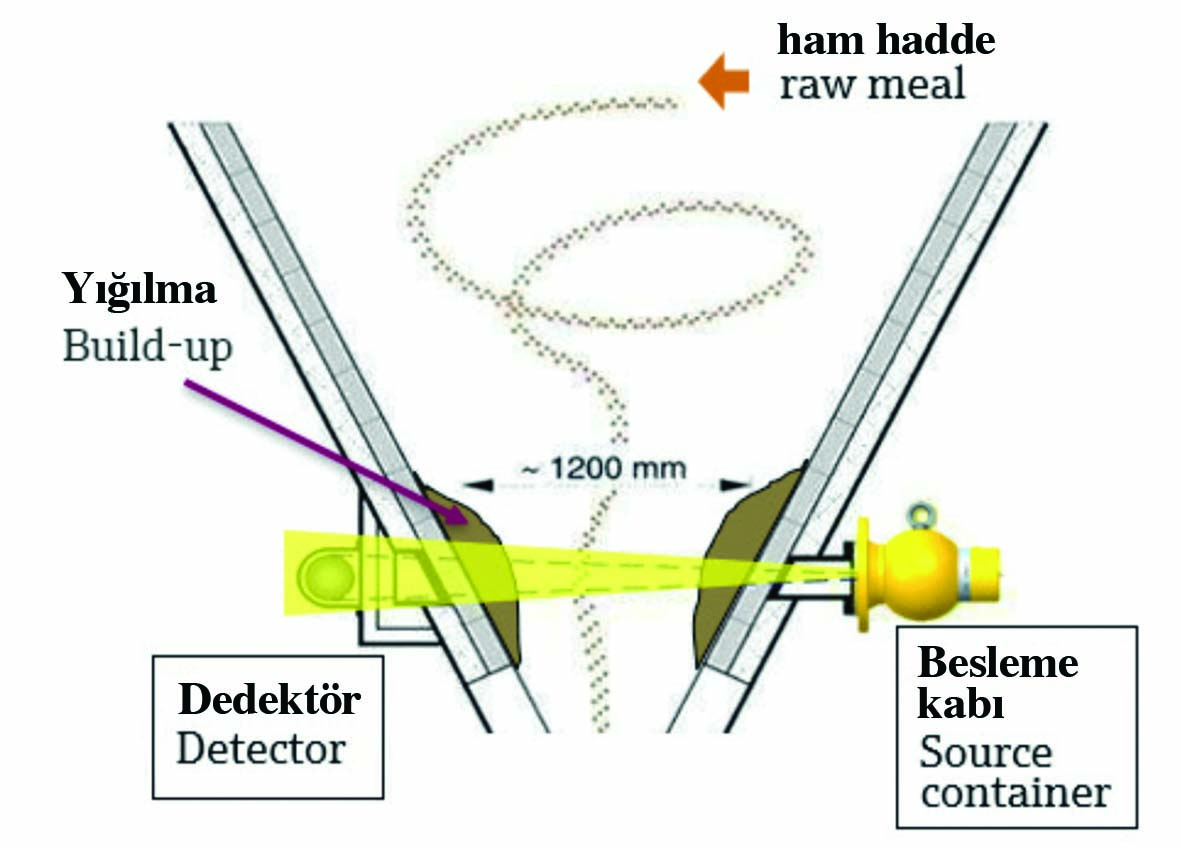

Monitoring Cyclone Preheaters

Cyclone preheaters need to be monitored to control the blending of the the raw meal and to prevent blockages which could result in costly down-time. Apart from temperature as a base parameter for overall efficiency , measuring pressure and actual build-up can help detecting blockages.

• Latest in high-tech, abrasion-proof alloy thermocouples with vibration-resistant electronics for long-life temperature monitoring

• High-accuracy, thermal, shock-resistant sensors for cyclone chamber pressure control

• Non-invasive cyclone buildup and blockage detectors

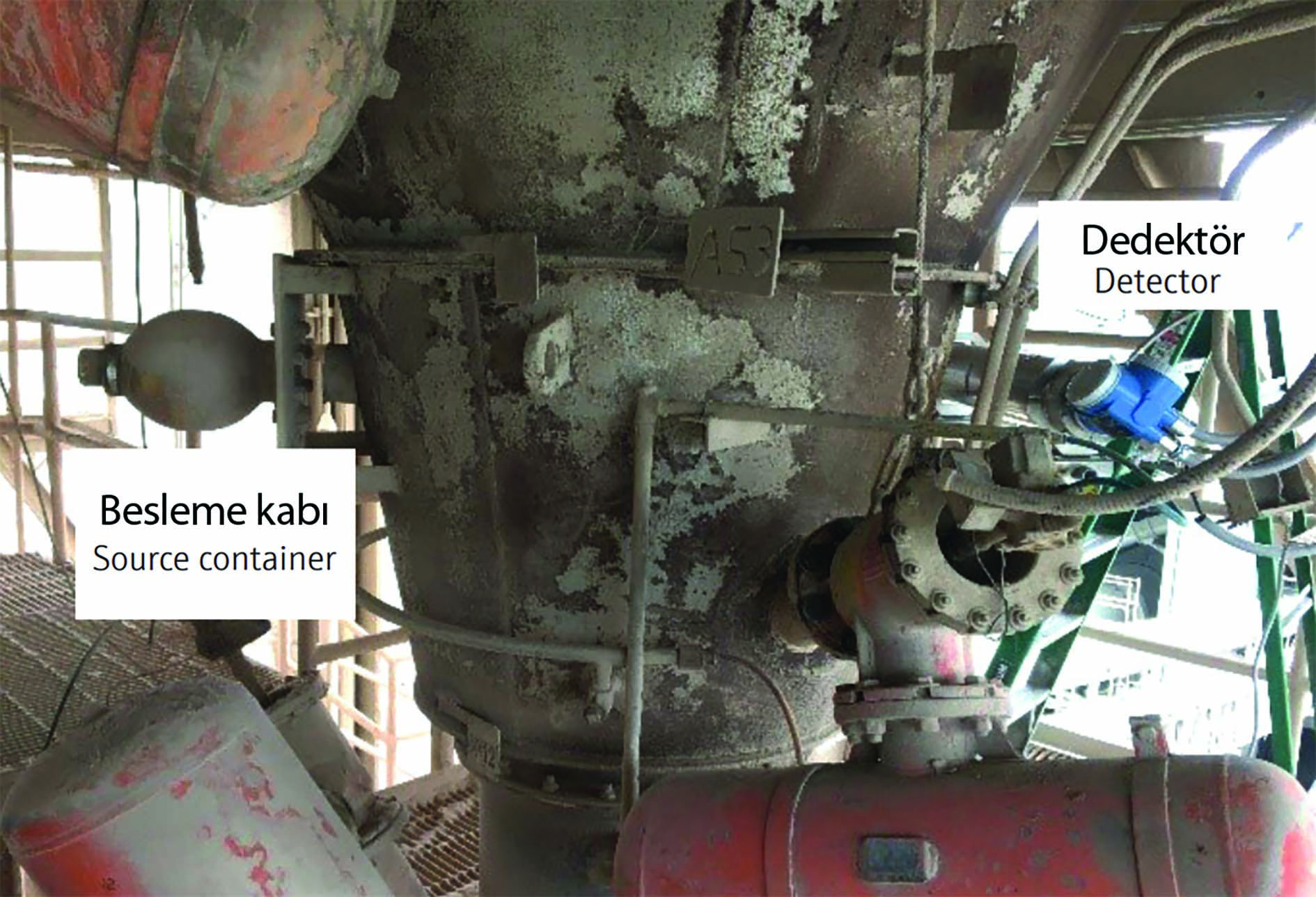

Traditional Solution for Monitoring Cyclone Blockage

Extreme process temperatures, high abrasion and heavy build-up rule out all measurement technologies that are directly exposed to the process. In this scenario, radiometric measurement provides a convenient alternative wherein a gamma source is used to penetrate the thick walls of the vessel and a detector is employed to detect the absorption of the gamma radiation by the process. The absorption of gamma radiation indicates the build-up present in the beam path. However, the high ambient temperatures around the cyclone affect the performance of the detector as well. Plant owners therefore provide a large piping network so that water can circulate around the detector to maintain its temperature. The additional water jacket around the detector also mandates a higher source activity so that the radiation is beyond the minimum threshold of the detector.

The new Gammapilot FMG50 from Endress+Hauser offers a significant upgrade compared to conventional radiometric solutions. As the first 2-wire loop-powered compact transmitter, the Gammapilot reduces engineering and installation efforts. The high temperature sensor technology allows the use of the device without additional water cooling up to 80°C which leads to savings in installation and operation. The device is also equipped with Bluetooth® wireless technology which ensures an easy operation out of the radiation beam and at a distance to high ambient temperatures.

The best solution in order to achieve high-quality cement and consistently high production levels can be realized by installing industry optimized, field-proven instrument technology backed by 70 years of cement process know-how. Whether you need to prepare and meter a fuel mix, clean up your gas and liquid emissions to comply with local environmental standards or simply need a professional technician to set up level instruments in your cement silo, you can be confident that Endress+Hauser will serve your needs and support your ambitions.