Serkan ÇAYIRLI *1, Hasan Serkan GÖKÇEN2

1Niğde Ömer Halisdemir University, Faculty of Engineering Department of Mining Engineering, Niğde, Türkiye

2Eskişehir Osmangazi University, Faculty of Engineesring and Architecture Department of Mining Engineering, Eskişehir, Türkiye

*Corresponding author; e-mail: scayirli@ohu.edu.tr

ABSTRACT

The flowability of powders and bulk solids is a critical parameter affecting process continuity, energy efficiency, equipment design, and operational performance in industrial applications. Particularly in mineral processing and the cement industry, the flowability behaviour of fine particles resulting from grinding directly influences process capacity, efficiency, and product quality. This review systematically examines the most commonly used methods for characterizing powder flowability reported in the literature, including angle of repose, Hausner ratio, Carr index, flow rate through an orifice, shear cell testing, and sieving-based methods. In addition, recent scientific studies investigating the effects of different types of grinding aids on powder flowability are critically evaluated.

The literature consistently demonstrates that grinding aids improve powder flowability by reducing interparticle interactions, with these effects being reliably identified through various flowability measurement techniques.

- INTRODUCTION

Powders and bulk solids are processed or stored across almost all industries, ranging from powder coatings and food products to nanoscale powders and pharmaceutical materials, as well as cement, coal, ores, dry materials such as fly ash, and moist bulk solids such as filter cake and clay (Schulze, 2008). Powder handling typically involves various unit operations, comprises feeding, aeration, fluidization, pneumatic conveying, mixing, grinding, classification, compaction, and storage in hoppers or silos (Leturia et al., 2014; Krantz et al., 2009; Prescott and Barnum, 2000; Schulze, 2008). A comprehensive understanding of powder flowability—which plays a vital role in the reliable design and consistent operation of powder handling equipment—is essential to prevent undesirable flow problems such as arching(bridging), channelling, segregation, irregular or unstable flow, agglomeration, and buildup during discharge from silos, hoppers, conveying systems, or mills (Schulze, 2008; Guiling et al., 2018).

In mineral processing and cement industries in particular, the transport and flow behaviour of materials ground at high throughput inside mills significantly affects energy consumption, capacity, and overall efficiency. As particle size decreases, the use of grinding chemicals becomes necessary to prevent material accumulation inside the mill, ensure sufficient particle flow within the mill discharge, and enable effective force transfer from grinding media to particles (Figure 1). These chemicals must be used at optimal dosages during these process stages. While the effects of grinding aids on energy consumption, capacity, and particle size distribution are frequently reported, it is therefore important to emphasize that their primary effect is associated with powder flowability properties rather than solely with grinding performance. (Çayırlı et al., 2022).

Figure 1. Particle arrangements with and without grinding aids (cross-sectional view) (highly dispersed powder); (a) without grinding aid, (b)/(c) with grinding aid; in Figure (c), the surface is completely covered (Schulze, 2008).

The primary objective of this review is to comparatively evaluate powder flowability measurement methods and systematically present the reported effects of grinding aids based on these methods.

- MEASUREMENT OF POWDER FLOWABILITY

Powder flowability is a critical parameter that should be evaluated prior to processing in order to prevent blockages and material losses along the production line. It is equally important for ensuring product performance and designing hoppers that allow reliable powder discharge (Shah et al., 2023). In the literature, many researchers have employed different test devices and/or approaches to measure powder flowability and to provide evidence or characterization for their studies. The four most frequently reported methods are: (i) angle of repose, (ii) compressibility index or Hausner ratio, (iii) flow rate through an orifice, and (iv) shear cell testing. In addition, sieving analysis and residence time measurements in mills have also contributed to the literature.

2.1. Angle of Repose Method

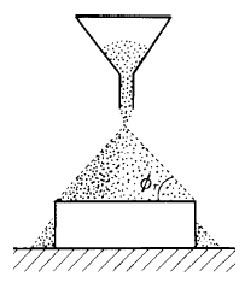

The static angle of repose (θ) is defined as the angle between the horizontal plane and the slope of a powder heap formed when material is poured onto a flat surface (Figure 2). The most characteristic feature of the heap is the angle of repose. Depending on environmental conditions and the measurement method, different angle values may be obtained for the same powder, indicating that it is not an intrinsic material property. Measurement techniques and experimental parameters significantly influence the results; therefore, published angle of repose values are not always directly comparable (Juliano and Barbosa-Cánovas, 2010).

The angle of repose is calculated using Equation (1), where α is the angle of repose, h is the height of the powder heap, and r is the radius of the circular base. A general flowability classification based on angle of repose is presented in Table 1 (Powder Flow, 2012).

tan (α) = h/r (1)

Figure 2. Static angle of repose method (Juliano and Barbosa-Cánovas, 2010).

| Flow property | Angle of repose (°) |

| Excellent | 25-30 |

| Good | 31-35 |

| Fair | 36-40 |

| Passable | 41-45 |

| Poor | 46-55 |

| Very poor | 56-65 |

| Extremely poor | >66 |

Table 1. Flowability classification based on angle of repose (Powder Flow, 2012).

Zhang et al. (2015) evaluated cement flowability using the angle of repose method. Compared to the reference sample, the presence of a polymer-based grinding aid resulted in more rounded and finer cement particles. Furthermore, the polymer-based grinding aid significantly reduced the angle of repose of the ground cement from 66° to 37°.

2.2. Hausner Ratio and Compressibility Index (Carr Index)

In recent years, the compressibility index and the closely related Hausner ratio have become simple, rapid, and widely used methods for predicting powder flowability. A powder sample is carefully poured into a graduated cylinder up to 100 ml and weighed to determine the bulk density (DB). The cylinder is then tapped 1500 times using a tapped density tester until no further volume change occurs, yielding the tapped density (DT).

The Hausner ratio and Carr index are calculated using Equations (2) and (3), respectively (Carr and Ralph, 1965). In free-flowing powders, bulk and tapped densities are similar, resulting in a low Carr index. In contrast, powders with strong interparticle interactions exhibit larger differences between bulk and tapped densities and consequently higher Carr index values (Table 2) (Katircioglu-Bayel, 2023).

HR = DT / DB (2)

CI = ( DT – DB)/DT (3)

| Flow Property | Carr index | Hausner ratio |

| Excellent | ≤10 | 1,0-1,11 |

| Good | 11-15 | 1,12-1,18 |

| Fair | 16-20 | 1,19-1,25 |

| Passable | 21-25 | 1,26-1,34 |

| Poor | 26-31 | 1,35-1,45 |

| Very Poor | 32-37 | 1,46-1,59 |

| Extremely Poor | >38 | >1,60 |

Table 2. Flowability classification based on Carr index and Hausner ratio.

Katircioglu-Bayel (2023) investigated the flowability of calcite micronized in a stirred ball mill using grinding aids such as triethanolamine (TEA), diethylene glycol (DEG), and ethanol (EtOH). Flowability characterization based on Carr index and Hausner ratio indicated that the lowest Hausner ratio—corresponding to excellent flow—was obtained with TEA, whereas the highest value—indicating extremely poor flow—was observed without grinding aid. DEG exhibited good flowability, while EtOH showed passable flow. Carr index values were determined as 32 (very poor) without grinding aid, and 9.59 (excellent), 14.45 (good), and 21.9 (passable) for TEA, DEG, and EtOH, respectively.

2.3. Flow through an Orifice Method

Numerous particle- and process-related factors influence powder flow rate, making it a practical indicator of flowability. However, flow rate measurements through an orifice are only applicable to free-flowing materials. Flow rate is generally measured as mass or volume discharged per unit time from a container. Three key experimental variables affect the measurement: the container geometry, the size and shape of the orifice, and the method used to determine flow rate. Although mass flow rate is easier to measure, it tends to favor denser materials. Since many industrial filling operations are volumetric in nature, volumetric flow rate is often preferred. Because flow rate is highly dependent on the measurement methodology, no universal classification scale exists. Flow through an orifice is not an intrinsic material property and is therefore method-dependent (Shah et al., 2023).

2.4. Shear Cell Methods

Various shear cell test devices and methodologies have been developed to enable comprehensive and precise evaluation of powder flow properties and to relate powder behaviour to hopper design. These methods provide parameters such as yield locus, internal friction angle, unconfined yield strength, tensile strength, flow function, and other flowability indices, which are widely used for determining critical hopper and silo design parameters. Shear cell methods have also been systematically applied to characterize the flow behaviour of micronized products produced using grinding aids and to optimize grinding circuits, including mills, classifiers, and auxiliary equipment.

Two commercially prominent shear cell devices are widely used: the ring shear tester developed by Dr. Dietmar Schulze (RST-XS) and the Powder Flow Tester (PFT) by Brookfield Engineering Laboratories Inc. (Figure 3). The PFT complies with ASTM D6128 (ring and Jenike shear testing techniques), while the RST conforms to ASTM D6773. Both devices are extensively used in industrial and research applications. The fundamental measurement principle of both RST and PFT is the determination of the powder yield locus (Figure 4), which represents the stress required for powder flowability after consolidation. A Mohr stress circle describes the stress state during consolidation, defining the major principal consolidation stress σ₁. Another Mohr circle passing through the origin represents the stress state under unconfined compression, defining the unconfined yield strength σc. The ratio of σ₁ to σc yields the flow function or flowability index (ffC), as given in Equation 4.

Figure 3. Ring shear tester (left) (Schulze, 2008) and Powder Flow Tester (right) (Çayırlı et al., 2023).

Figure 4. (a) Yield/failure locus and Mohr circles in the normal stress (σ) and shear stress (τ) diagram; Mohr circles define the consolidation stress σ₁ (MSC) and unconfined yield strength σC (UYS). (b) Schematic representation of flow behavior based on flow function (ffC) (Slettengren et al., 2016).

ffc = σ1/σC (4)

According to Jenike (1964), the ffC value can be used to classify the flowability of powders into different categories. For example, a powder is described as non-flowing, cohesive, easy-flowing, and free-flowing when ffC < 1, 2 < ffC < 4, and 4 < ffC < 10, respectively.

In their study, Prziwara et al. (2018) ground calcitic limestone to micronized sizes in a vibratory mill using various grinding aids (amine-based, glycol-based, alcohol-based, and carboxylic acids) and systematically and consistently characterized the powder flowability of the resulting products using Dr. Dietmar Schulze’s ring shear tester. In another study, Cayirli et al. (2023) investigated the use of waste and by-product liquids (pomace oil and olive mill wastewater) as grinding aids for micronizing calcite in a stirred ball mill and compared their performance with that of pure commercial grinding aids. In their research, the effects of the grinding aids on the powder flowability of the products were evaluated using a PFT device in a reliable and reproducible manner.

2.5. Sieving Method

This method is based on determining flowability by measuring the rate at which particles finer than a specified size pass through a sieve within a given time. For flowability determination, 200 g of sample is sieved on a vibrating sieve with a mesh size of 75 µm (or finer) as a function of time. A flowability index is then calculated using Equation (5), where P is the mass passing through the sieve at time t, Pₘₐₓ is the maximum passing mass, and b is the flowability index (Morasse et al., 2007).

P/Pmax = bt/1+bt (5)

Morasse et al. (2007) tested nineteen different grinding aids during cement grinding and compared the flowability indices of the resulting products using the sieving method. In another study, Çayırlı (2022) characterized the effects of various grinding aids (pure chemicals, commercial products, and water) on the flowability of micronized calcite using the same method. Despite its limited repeatability, this method proves to be a practical tool for comparative assessments and benchmarking against conditions without grinding aids, particularly under limited or controlled conditions.

- CONCLUSIONS

This review systematically examined the principal methods used to characterize the flowability of powders and bulk solids and evaluated the effects of grinding aids on powder flow behaviour based on literature studies. The findings indicate that, for industrial applications, powder flowability should be assessed using multiple complementary measurement methods. In particular, for critical processes and equipment design, shear cell testing provides more reliable and representative results.

When selecting and dosing grinding aids, not only grinding performance but also the resulting powder flow properties should be considered. Accordingly, the effects of grinding aids with different chemical structures on flowability should be evaluated under standardized and comparable testing conditions.

Overall, the reviewed studies demonstrate that powder and bulk solid flowability cannot be adequately described using a single measurement technique in most cases. While simple methods such as angle of repose, Hausner ratio, and Carr index are useful for rapid preliminary assessments, shear cell–based measurements are essential for reliably characterizing the flow behaviour of fine and cohesive powders. Furthermore, the combined interpretation of parameters obtained from different flowability measurement methods enables a more accurate and comparable evaluation of the effects of grinding aids on powder flow behaviour.

REFERENCES

Leturia, M. Benali, S. Lagarde, I. Ronga, K. Saleh, Characterization of flow properties of cohesive powders: a comparative study of traditional and new testing methods, Powder Technol. 253 (2014) 406–423.

Krantz, H. Zhang, J. Zhu, Characterization of powder flow: static and dynamic testing, Powder Technol. 194 (2009) 239–245.

J.K. Prescott, R.A. Barnum, On powder flowability, Pharm. Technol. 24 (2000) 60–84.

Xu Guiling, Lu Ping, Li Menghui, Liang Cai, Xu Pan, Liu Daoyin, Chen Xiaoping. Investigation on characterization of powder flowability using different testing methods. Experimental Thermal and Fluid Science 92 (2018) 390–401.

Çayırlı, H.S. Gökçen, N. Yüce, O. Elchi, 2022. Atık malzemelerin ve yan ürünlerin kalsitin öğütülmesinde öğütme yardımcısı olarak kullanımının araştırılması. 3501-Kariyer Projesi, TÜBİTAK.

D.S. Shah, K.K. Mo ravkar, D.K. Jha, V. Lonkar, P.D. Amin, S.S. Chalikwar, A concise summary of powder processing methodologies for flow enhancement, Heliyon, 9 (6), (2023), e16498.

Juliano, G.V. Barbosa-C´anovas, Food powders flowability characterization: theory, methods, and applications. Annu. Rev. Food Sci. Technol. (2010) 1:211–39.

Powder Flow, United States Pharmacop., 2012, pp. 801–804.

Zhang, J. Gao, J. Hu, Preparation of polymer-based cement grinding aid and their performance on grindability, Constr. Build. Mater. 75 (2015) 163–168.

J.R. Carr, L. Ralph, Evaluating flow properties of solids Chem. Eng. 18 (1965) pp. 163-168.

Katircioglu-Bayel, Effective role of grinding aids in the dry grinding performance of calcite, Powder Technology, 426 (1), (2023) 118675.

Schulze, 2008. Powders and bulk solids: Behavior, characterization, storage and flow. Sringer-Verlag Berlin Heidelberg.

Çayırlı, H. S. Gökçen, N. Yüce, O. Elchi, Utilization of wastes/by-products as grinding additives, Scientific Mining Journal 62 (3), (2023) 123 – 130.

Slettengren, E. Xanthakis, L. Ahrné, E. J. Windhab, Flow properties of spices measured with powder flow tester and ring shear tester-XS. International Journal of Food Properties, 19 (2016) 1475–1482.

A.W. Jenike. Storage and flow of solids, Bull. Utah Eng. Exp. Station. 123 (1964).

Prziwara, S. Breitung-Faes, A. Kwade, Impact of grinding aids on dry grinding performance, bulk properties and surface energy, Adv. Powder Technol. 29, (2018) 416–425.

Cayirli, H.S. Gokcen, N. Yuce, O. Elchi, Investigation of the usage of waste materials and By-Products as grinding aids in calcite grinding. Minerals Engineering. 202 (2023) 108267.

Morasse, J. Jolicoeur, J. Sharman, A. Tagnit-Hamou, F. Slim, M. Pagé, Polyoltype Compounds as Clinker Grinding Aids: Influence on Powder Fluidity and on Cemen Hydration, in: 12th Int. Congr. Chem. Cem., (2007), pp. 3–4.