Heat transfer through a structure is of great importance in civil engineering while planning the design of a building for thermal comfort. The knowledge of thermo-physical properties of construction materials is essential in predicting the temperature profile and heat flow through the material. It is known that aggregate type significantly affect the thermo-physical properties of concrete. In this study, thermal conductivity and moisture resistance factor are investigated for concretes with different types of aggregates including calcareous, siliceous and pumice. According to the test results it was seen that the thermo-physical properties of concrete is directly influenced by the type, pore structure and crystallinity of the aggregates.

Keywords: Concrete; aggregate; thermal conductivity; moisture resistance factor.

1. Introduction

Concrete is a widely used construction material commonly made by mixing Portland cement with sand, crushed rock, and water [1]. The aggregate in concrete occupies 60 to 80 % of the volume and thus has an important effect on thermo-physical properties of concrete such as thermal conductivity and moisture resistance factor.

Heat transfer through a structure is of great importance in civil engineering while planning the design of a building for thermal comfort. The knowledge of thermal conductivity and other thermal transport properties of construction materials are essential in predicting the temperature profile and heat flow through the material. The type of aggregate, porosity and moisture content have the maximum influence on thermo-physical properties of concrete [2].

During the transition of water vapor through a construction element, condensation might occur according to the heat and water vapor resistance of the materials that constitute this construction element and the alignment of the layers in this element. This is an undesired occasion in a construction element and must be controlled according to TS 825 in which thermal insulation requirements are given. In this control, thermal conductivity and moisture resistance factor of the materials are taken into consideration [3]. Moisture resistance factor differs for each construction materials and is determined according to TS EN 12086 [4]. Calculation values for moisture resistance factor determined according to this standard are given in TS 825.

Thermal conductivity is the property of material that plays an important role in heat transfer calculations. Heat transfer in porous materials involves heat conduction in solid materials, heat conduction through pore, convection heat transfer through pore, radiation from solid surfaces of pores, and evaporation and condensation in the pores [5]. Condensation occurs when the temperature of a vapor is reduced below its saturation temperature. This is usually done by bringing the vapor into contact with a solid surface whose temperature is below the saturation temperature of the vapor [6].

Moisture greatly influences the performance and durability of building materials, and thus is one of the most important factors limiting a building’s service life. Besides, moisture can cause changes in the appearance and physical properties of materials such as metal corrosion, rotting in woods, and peeling of paint on the interior and exterior wall surfaces. Studying the coupled heat and moisture transport behavior of porous building materials is essential to improving their performances [6,7].

Thermal conductivity and moisture resistance factor are the two main parameters used in planning the thermal design of a building. Although much work has been done on the thermal conductivity of concrete, relatively little work has been done on the moisture resistance factor of concrete. In this paper, concretes with different types of aggregates including calcareous, siliceous and pumice were prepared and the effect of aggregate type on thermal conductivity and moisture resistance factor is investigated.

2. Experimental Study

2.1. Materials and specimen preparation

Experimental study consists of concrete production, curing and testing. A total of three series of concrete namely C1, C2 and C3 were made with ordinary Portland cement (CEM I 42.5 R), three types of aggregates and superplasticizer. Concrete series were coded according to the aggregate types. C1 was made of siliceous aggregates, C2 was made of calcareous aggregates and C3 was made of pumice and calcareous crushed stone sand aggregates. Physical properties of aggregates are given in Table 1.

In each concrete series in order to determine thermal conductivity and moisture resistance factor of concrete, plate specimens with dimensions of 300x300x40 mm and cylinder specimens with dimension of 100/40 mm were cast respectively. Specimens were demoulded 24 hr after the production and then stored in a water tank at 20±2°C until testing. Mix proportions and fresh concrete properties are given in Table 2.

2.2. Tests

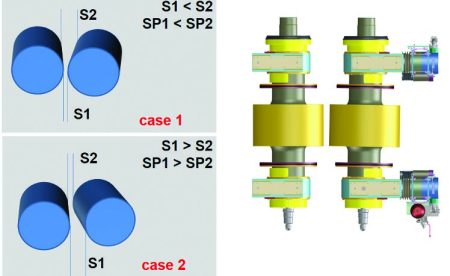

In each series, slump and density were determined in fresh concrete; density, compressive strength, thermal conductivity and moisture resistance factor were determined in hardened concrete. Compressive strength and density of hardened concrete were conducted on 100/200 mm cylinder specimens according to TS EN 12390-3 and TS EN 12390-7 respectively. Thermal conductivity test was performed by using guarded hot plate apparatus (Fig. 1) in accordance with TS ISO 8302.

3. Test Results and Discussion

3.1 Thermal Conductivity

Thermal conductivity of the concretes varied between 0.48-2.05 W/mK (Table 3). The highest thermal conductivity was observed in C1 series as 2.05 W/mK with siliceous aggregate and the lowest was observed in C3 series with pumice aggregates as 0.48 W/mK. Pumice as a natural lightweight aggregate has better thermal insulation properties compared to normal weight aggregates [8] and therefore improves thermal properties of concrete. Concrete made with calcareous aggregates (C2) had a similar but a bit lower thermal conductivity of 1.98 W/mK compared to C1. The reduction in the thermal conductivity can be explained by the fact that the thermal conductivity of calcareous aggregates is lower than that of the siliceous aggregates [9]. This is due to the higher crystallinity of the siliceous aggregates as compared with that of carbonate aggregates [10].

3.2. Moisture resistance factor

Table 3 shows the results of the moisture resistance factors of the concretes. Among all series, C2 had the highest moisture resistance factor (67). Moisture resistance factor of C1 and C3 were 35 and 15 respectively. As reported by several researchers, moisture permeability of concrete is a function of porosity and density. An increase in porosity results in an increase in moisture permeability. However moisture permeability is adversely affected by density [11,12]. In this study, moisture resistance factor of C3 concrete with pumice aggregates had the lowest value. Due to its lower density and higher porosity, it is natural for C3 concrete to have a lower moisture resistance factor than the other concretes. When we consider C1 and C2 series, although their densities had close values (2371 and 2334 kg/m3 respectively), moisture resistance factor of C2 was approximately two times of C1. Ollivier et al. [13] has reported that the microstructure of the interfacial transition zone may be improved in the vacinity of calcareous aggregate, which reacts with calcium aluminates of Portland cement paste, forming calcium carboaluminates. The improvement in the interfacial transition zone would therefore decrease moisture diffusion and increase the moisture resistance factor of concrete [14].

4. Conclusions

Based on the results obtained in this study, the following conclusions can be summarized.

1. Different type of aggregates with different pore structures and crystallinity directly influence the thermo-physical properties of concrete.

2. While concretes with porous lightweight aggregates such as pumice exhibit lower thermal conductivity, concretes with aggregates having higher crystallinity such as siliceous exhibit higher thermal conductivity.

3. Moisture resistance factor varied in a wide range between 15 and 67. Although moisture diffusion is closely related with pore structure of both aggregate and concrete, interfacial transition zone also affects this property. Although siliceous and calcareous aggregate concretes have similar densities, moisture resistance factor of concrete with calcareous aggregate is almost twice of concrete with siliceous aggregate. The usage of calcareous aggregate in concrete has provided an improvement at the interfacial transition zone and has lead to an increase in moisture resistance factor.

4. Thermo-physical properties such as thermal conductivity and moisture resistance factor are important in planning thermal design of buildings. Thus the knowledge of these properties for concretes with different aggregates will help to provide an accurate thermal design.

Acknowledgements

This research was carried out in the Faculty of Civil Engineering at Yıldız Technical University. The authors wish to acknowledge the financial supports provided by Yıldız Technical University Research Fund and The Scientific and Technological Research Council of Turkey.

References

[1] Mehta KP. Monteiro PJM. Concrete, microstructure, properties and materials. 3rd ed. Newyork: McGraw-Hill; 2006.

[2] Khan MI. Factors affecting the thermal properties of concrete and applicability of its prediction models, Build Environ 2002;37:607-14.

[3] TS 825 “Binalarda Isı Yalıtım Kuralları”, Mart 2008.

[4] TS EN 12086 “Isı Yalıtım Malzemeleri-Binalar İçin-Su buharı Geçirgenlik Özelliklerinin Tayini”, 2002.

[5] Bhattacharjee B, Krishnamoorthy S. Permeable porosity and thermal conductivity of construction materials. J Mater Civil Eng 2004; 16:322-30.

[6] Çengel Y. Heat and mass transfer a practical approach. Singapore: McGraw-Hill; 2006.

[7] Qin M, Belarbi R, Mokhtar AA, Nilsson LO. Coupled heat and moisture transfer in multi-layer building materials. Constr Build Mater 2009;23:967-75.

[8] Neville AM. Properties of concrete. 4th ed. Newyork: Longman Scientific and Technical; 2000.

[9] Bazant ZP. Kaplan MF. Concrete at high temperatures. London: Longman Group Limited; 1996.

[10] Kodur VKR, Sultan MA. Effect of temperature on thermal properties of high-strength concrete. J Mater Civil Eng 2003; 15:101-7.

[11] Kabay N. The effect of pore structure on mechanical and physical properties of lightweight aggregate concrete. PhD Thesis, Yıldız Technical University, Istanbul; 2009.

[12] Kearsley EP, Wainwright PJ. Porosity and permeability of foamed concrete. Cem Concr Res 2001; 31:805-12.

[13] Ollivier JP, Maso JC, Bourdette B. Interfacial transition zone in concrete. Adv Cement Based Mater 1995; 2:30-8.

[14] Kızılkanat AB. Investigation of the relationship between compressive strength and color change of concrete subjected to high temperatures. PhD Thesis, Yıldız Technical University, Istanbul; 2010.