Cement sector has always adopted a challenging process structure for level measurement. The reason for that is the factors such as contaminations and adherences on the sensor caused by intense dust formation, high temperature, abrasive substances (dustaggregate). VEGA had developed various user-friendly instruments which offer trouble-free operation in such challenging processes many years ago. The instruments it has developed are running with maximum assurance against challenging process factors for long years. We are able to measure the level of each process in cement plants. If to give an example from a difficult process, we are able to measure up to the lava level in clinker cooling with a temperature of 1300oC. The typical problem experienced in non-contact radar level sensors is the negative influence on level measurement due to material adhering on the probe. With 80GHz(VEGAPULS 69) radar technology we have developed, contaminations on the antenna will not have negative influence on the measurement. In other words, you will not be required to deliver cleaning air to radar level sensor or to clean the antenna continually.

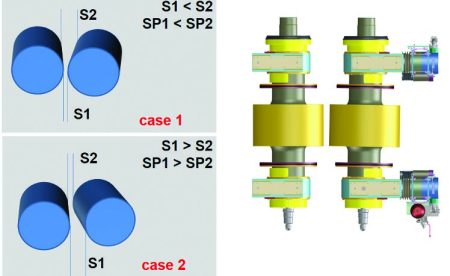

The same applies to our level switches. The device will not signal full indication even if the material in the silo adheres on the sensor rod, unless it is submerged in the material thanks to our vibratory or capacitive level sensors.

One of the most problematic processes in cement plants is cyclones. Failure to detect the extent of congestion in the cyclone

beforehand may cause sudden stoppage of your plant. In this case, we may offer you a solution with our radioactive based instruments. A process temperature of 900oC at this point does not also constitute a problem for VEGA. You can measure the accumulation thickness on the sidewalls of your cyclone with VEGASOLITRAC 31. This measurement method allows you to continuously monitor the change inside the cyclone and to detect the potential congestions beforehand.

Ceramic diaphragm pressure transmitters (VEGABAR 82) which employ VEGA’s proprietary technology offers the required precision at very low pressures or under vacuum. You can perform trouble-free measurements with our ceramic diaphragm pressure transmitters for long years without erosion issues even if air flow bearing solid particles is present in your process.

VEGA instruments have a compact structure. You can adjust all of the instruments on your site with a display you have on hand. All of these instruments feature Turkish language support and quick setup menu. These features highlight VEGA as a user-friendly brand.

One of the most important features required in such kind of products is technical service. Entire staff of VEGA possesses the required technical know-how. This will offer you major conveniences in product selection and after-sales services.