THE RELATION BETWEEN AUTOGENOUS SHRINKAGE AND HYDRATION STAGES – hıgh performance cement based panel applicatıons

Bekir Y. PEKMEZCİ

Istanbul Technical University, Istanbul, Turkey

Abstract

Autogenous shrinkage concept has started to gain more importance since the high performance-high strength concretes were began to utilize for structural purposes. These concretes are generally designed with high cementitious materials contents and low water to cementitious material ratios. It is observed that, due to lack of water in capillary pores in these concretes, autogenous shrinkage increases under the effects of not only the chemical factors but also the physical effects.

The relation between autogenous shrinkage and hydration stages were experimentally investigated in this study. Long term setting retarder (stabilizer) were used in order to extend hydration times. Autogenous shrinkages of these specimens were obtained. Chemical shrinkage, determination of released heat of hydration and determination of setting times tests were applied on the paste specimens in order to monitor hydration.

The main results obtained from this experimental study can be drawn as following:

Autogenous shrinkage has three main phases and these phases can be related to some hydration stages. The most effective factor in gaining the autogenous shrinkage was the released heat values which show the rate of hydration. Higher autogenous shrinkage values were measured for the cement pastes which had higher values of released heat.

1. Introduction

Autogenous shrinkage concept has become very important issue in recent years with production of high performance-high strength concretes. It is a true approach to accept the autogenous shrinkage as an physicho chemical phenomenon. The well isolated high performance (very low water to cement ratio) cement pastes gets hydrated by absorbing internal water in micro pores. Capillary pore diameters gets narrower and the effective tensile force on the pore edges gets higher. Consequently; macro deformation which is called autogenous shrinkage occurs [1-9].

There are many factors effective on autogenous shrinkage. It is reported that fineness of cement is very effective factor on autogenous shrinkage [10]. Furthermore, discussions on the effectiveness of the compounds are still present [2,10-13].

Usage of mineral and chemical admixture [2,14-16], temperature [17,18], usage of aggregate [2] are the important parameters which effect the autogenous shrinkage values.

There are couple of studies which investigated the relations of autogenous shrinkage behaviour with hydration reactions and setting times. Nawa et. al [16] have done some investigations on the stages of autogenous shrinkage. Garcia and Boivin [19], Baroghel et al. [20] and Justness et. al. [21] investigated the relations between setting times and autogenous shrinkage knee points.

Although numbers of experimental works conducted, there are serious contradictions between the conclusions of these papers.

The relation between autogenous shrinkage and hydration stages were experimentally investigated by manipulating setting times and hydration process of Type 1 cement in this study.

2. Experımental detaıls

2.1 Materials and mix proportions

CEM I ordinary Portland cement 42.5 was used for production of cement pastes. Physical, chemical and mechanical properties of cement are given in Table 1,2 and 3.

Table 1: Physical properties of cement

| Specific Gravity (g/cm3) |

3.09 |

| Remaining on 90μm sieve (%) |

1 |

| Remaining on 200μm sieve (%) |

0 |

| Specific Surface Area (Blaine) (cm2/g) |

3070 |

| Water of consistency (%) |

29 |

| Le Chatelier Opening (mm) |

2 |

| Initial Setting Time (Hour:Minute) |

3:00 |

| Final Setting Time (Hour:Minute) |

5:15 |

Table 2: Chemical properties of cement

|

Chemical Composition |

(%) |

Chemical Composition |

(%) |

| SiO2 |

18,8 |

K2O (total) |

1,18 |

| Al2O3 |

5,56 |

Na2O (total) |

0,32 |

| Fe2O3 |

3,47 |

K2O (soluble) |

0,705 |

| CaO |

62,80 |

Na2O (soluble) |

0,142 |

| MgO |

2,42 |

C3S |

57,05 |

| SO3 |

2,78 |

C2S |

10,92 |

| Unsoluble residue |

0,38 |

C3A |

8,86 |

| Ignition loss |

2,52 |

C4AF |

10,56 |

| Free lime |

1,31 |

Table 3: Mechanical properties of cement

|

Age (days) |

C2 |

|

| Tensile Strength at Bending (N/mm2) |

7 |

6,6 |

|

28 |

7,3 |

|

| Compressive Strength (N/mm2) |

7 |

32,2 |

|

28 |

46,4 |

Two types of chemical admixtures were used in production process of specimens. Polyycarboylate based superplasticizer was used to reduce the water to cement ratio, stabilizer was used as long term setting retarder.

Four series of paste specimens were produced. Mix proportions of the paste specimens are given in Table 4.

Table 4: Mix proportions of paste specimens

|

Specimen code |

Water / cement |

Superplasticizer (% of cement) |

Setting retarder (% of cement) |

|

020ST00 |

0.20 |

0.75 |

0.00 |

|

025ST00 |

0.25 |

0.00 |

0.00 |

|

025ST02 |

0.25 |

0.00 |

0.20 |

|

025ST04 |

0.25 |

0.00 |

0.40 |

One mix was produced with superplasticizer in order to see the effect of low water to cement ratio and the effect of superplasticizer admixture. Three series of the specimens do not contain superplasticizer in order to avoid any interaction between two different admixtures. The mix 025ST00 can be considered as control mix. Specimen code shows the mix proportions of the paste specimens. First number represents the water to cement ratio of the paste, the second number after ST shows the setting retarder percentage. 025ST00 shows the specimens produced with the water to cement ratio of 0.25 and the retarder content of 0.00%.

Autogenous shrinkage, chemical shrinkage, determination of hydration heat and setting time tests were conducted on the paste specimens. Specimens were transferred in test environment following mixing process.

2.2 Test methods

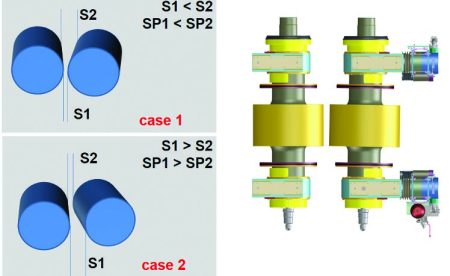

Volumetric measurement system was used for determination of autogenous shrinkage values. Cement paste specimen were transferred into a condom right after mixing process. This isolated paste specimen was hang under a0.0001 gprecision digital scale and weighed in water at every 15 minutes. A ressistance keeps the temperature of distilled water constant. Every data is recorded by means of a computer for every 15 minutes during 24 hours. Variation of the weight of the specimen in water gives the variation at the volume of the cement paste in condom. Test setup is given in Figure 1.

Figure 1: Autogenous shrinkage measurement system.

The measurement system for chemical shrinkage was the same as the system of autogenous shrinkage. Paste specimens were put in a open cup and weighed in water. Since the chemical shrinkage occurs inside of the specimen and forms the voids related to the hydration open mouthed cup was used. Chemical shrinkage values were calculated by weight increase of the paste specimens according to Archimedes rule.

Semi-adiabatic drum calorimeter was used in order to measure the released heat values during hydration. The data was recorded at every 15 minutes by means of a computer during 24 hours at hydration heat test. Standard automatic Vicat apparatus was used for the determination of setting times. Data was recorded at every 15 minutes at Vicat test.

3. TEST RESULTS AND DISCUSSIONS

Chemical shrinkage tests and hydration heat tests were conducted in order to monitor the hydration reaction rate. These two test results would be used in order to determine the critical points of the hydration reaction. Figure 3 illustrates the chemical shrinkage and hydration heat test results. First four stages of the hydration reaction according to Vernet’s [22] definition (mixing, dormant, setting and hardening periods) can be seen clearly seen for the paste specimens except the paste including 0.04% of setting control admixture. Hydration of the paste which does not include any chemical admixture is the earliest one. 025ST02 and 020ST00 mixes almost overlaps to each other and follows the plain mix for critical points of hydration.

Figure 3 : Chemical shrinkage and heat development of paste specimens.

025ST04 mix which has the maximum amount of setting retarder is the latest one on time scale in terms of the critical points of hydration.

Figure 4 shows the general development of autogenous shrinkage. It can be divided in three main stages. Nawa and Horita [19] has divided the autogenous shrinkage development into four main stages as initial, induction, acceleration and deceleration periods. The induction period was observed for none of the pastes. 1st, 2nd and 3rd periods can be called as initial, acceleration and deceleration periods respectively in this study.

Development of chemical shrinkage and heat of hydration are both the indicator of the hydration reaction. If the development of chemical shrinkage and heat of hydration are compared, two figures confirm each other. The critical points (knee points) are the same on time scale for both chemical shrinkage and heat of hydration.

|

|

|

|

|

Figure 4 : General trend of autogenous shrinkage development

The setting times which were determined by means of standard Vicat apparatus are given in Figure 5. Knee points of the autogenous shrinkage curves were determined from autogenous shrinkage-time charts. Knee points and setting times were compared in the figure. For the pastes do not include superplasticizer first knee points are between initial set and final set. Second knee point is over final setting time for 025ST00 and 025ST04 which is in between initial setting and final setting for 025ST025. Second knee point does not present a systematic behaviour with setting times. For the mix 020ST00 having superplasticizer and with the lower water to cement ratio, the times of first and second knee points are always longer than setting times.

Figure 5 : Setting times and knee points of the paste specimens.

Released hydration heats for unit time period was calculated in order to be used as an indicator of hydration rate. Figures 6-9 illustrates the autogenous shrinkage development and released hydration heat values of the paste mixes.

When the autogenous shrinkage behaviour of the mixes examined it can be said that; the curves of all the mixes have two knee points. The knee points are more significant for the mix having superplasticizer. Knee points are getting slighter with increase of SCA ratio.

Autogenous shrinkage curves should be compared with the released heat values in order to draw the relation between autogenous shrinkage and hydration. It is clear from the figures that the end of the dormant periods overlaps the first knee point. The beginning of hardening period fits to the second knee point.

| Figure 6 : Autogenous shrinkage and released heat development of the specimen 025ST00 | Figure 7 : Autogenous shrinkage and released heat development of the specimen 025ST00 | ||

| Figure 8 : Autogenous shrinkage and released heat development of the specimen 025ST02 | Figure 9 : Autogenous shrinkage and released heat development of the specimen 025ST04 | ||

In order to see the relation between the critical points of hydration and the knee points of autogenous shrinkage, derivatives of autogenous shrinkage values with time (dAS/dt) was calculated. The calculated values were compared with released heat values in Figures 10 and 11 for the mixes 025ST00 and 025ST02. Arrows in figures show the peak values of both dAS/dt and dQ/dt. It is clearly seen from the figures that the peak values of the two curves are observed at the same time period. The peak points at dAS/dt curve, corresponds the knee points at autogenous shrinkage time curve.

According to Vernert’s [22] definitions dQ/dt curve should start from a maximum value. Due to the testing apparatus it was not possible to obtain first maximum point. The curves started with dormand period of hydration in Figures 10 and 11. The plato illustrates the dormant period of hydration. Ettringite molecules surround the C3A molecules and prevent the hydration of them. During dormant period cement paste is in liquid form. As soon as the ettringite has got dissolved, C3S begins to get hydrated and dQ/dt curve start to get increased. Cement paste gets hardened during this period. After a peak point, hydration of C3S starts to loose the rate of its hydration and the curve has a decreasing trend. Following the sharp drop, a lowering trend continues until to the hydration ends. If dAS/dt curves are examined it is seen that the curve has first maximum value at mixing time. The curve makes a minimum at the age of the end of dormant period. It is possible to say that during dormant period, paste specimens gains a significant magnitude of autogenous shrinkage but this amount of autogenous shrinkage is not result from meniscus stresses. It is mostly caused by settlement of liquid paste specimen. Air voids in the paste and the air voids generated by the chemical shrinkage are reflected to the outer volume of the specimen by settlement. At second stage; paste gets hardened and hydration has a faster rate. Negative pressure in the capillary pores gets increased with hardening of the material. Cement paste is hard enough to be under effect of capillary pressure but it is not strong enough to resist the volume contraction. Because of this reason the paste exhibits the highest autogenous shrinkage value during this period. At the third period, cement paste is getting stronger and it can resist the negative capillary pressure and volume contraction.

| Figure 10: dQ/dt- dAS/dt relation for 025ST00 mix | Figure 11: dQ/dt- dAS/dt relation for 025ST02 mix |

4. Conclusions

The following conclusions can be drawn from this study;

- It is possible to divide autogenous shrinkage curve in three main stages. Development of these stages are related to the hydration reaction.

- There are two significant knee points in autogenous shrinkage-time curve

- The first knee point is between initial set and final set for the paste specimens do not contain superplasticizer. It was not possible to draw a certain conclusion about second knee point with setting times.

- First and second knee points overlaps the critical points of hydration. First knee point occurs at the end of dormant period, second knee point occurs at the beginning of deceleration period.

References

[1] Committee Report, Technical Committee on Autogenous Shrinkage of Concrete, Japan Concrete Institute, Proceedings of the International Workshop on Autogenous Shrinkage of Concrete,Hiroshima, 1998.

[2] Tazawa E., Miyazawa S.,-1 “Experimental Study on Mechanism of Autogenous Shrinkage of Concrete” Cement and Concrete Research, 25 (1995) 1633-1638.

[3] Tazawa E., Miyazawa S., KasaiT.,-2 “Chemical Shrinkage and Autogenous Shrinkage of Hydrating Cement Paste”, Cement and Concrete Research, 25 (1995) 288-292.

[4] Radocea, A., (1998) “Autogenous Volume Change of Concrete at Very Early Age” Magazine of

Concrete Research, 50, No.2, 107-113.

[5] Barcelo L, Boivin S., Rigaud S., Acker P., Clavaud B., Boulay C., “Linear vs. Volumetric Autogenous Shrinkage Measurement: Material Behaviour of Experimenal Artefact”, Self Dessication and Its Importance in Concrete Technology, Proceedings of the Second International Research Seminar in Lund, 1999, 109-125.

[6] Park K.B., Noguchi T., Tomosawa F., “A Study on The Hydration Ratio and Autogenous Shrinkage of Cement Paste” Proceedings of the International Workshop on Autogenous Shrinkage of Concrete,Hiroshima, 299-308

[7] Wild, S., Khatib., J., M., Roose L.J.,” Chemical Shrinkage and Autogenous Shrinkage of Portland Cement Metakaolin Pastes” Advances in Cement Research,1998,10, No.3, 109-119.

[8] Holt E.E., Leivo M.T., “Autogenous Shrinkage at Very Early Ages”, Proceedings of the International Workshop on Autogenous Shrinkage of Concrete,Hiroshima, 1998, pp. 135-142.

[9] Leivo M., Holt E., “Autogenous Volume Changes at Early Ages” Self Dessication and Its Importance in Concrete Technology, Proceedings of the Second International Research Seminar inLund,1997,89-98

[10] Bentz D.P., Geiker M.R., Hansen K.K. “ Shrinkage reducing admixtures and early age dessication in cement pastes and mortars”, Cement and Concrete Research, 31, Jul 2001, 1075-1085.

[11] Miyazawa S., Kuroi T., Tazawa E., “ Influence of chemical composition and particle size of cement on autogenous shrinkage” JSCE, Second International Conference on Engineering Materials, 2001.

[12] Tazawa E., Miyazawa S., “Influence of constituents and composition on autogenous shrinkage of cementious materials”, Magazine of Concrete Research,49, Mar 1997, 15-22.

[13] Justness H., Sellevold E.J., Reyiners B., Van Loo D., Gemert A.V., Verboven F., van Gemert D., “The Influence of Cement Characteristics on Chemical Shrinkage” Proceedings of the International Workshop on Autogenous Shrinkage of Concrete, Hiroshima, 1998.

[14] Brooks, J.J., Cabrera J.G., Megat Johari M.A., “Factors Affecting The Autogenous Shrinkage of Silica Fume High Strength Concrete”, Proceedings of the International Workshop on Autogenous Shrinkage of Concrete,Hiroshima, 1998. 195 – 202.

[15] Koenders, E.A.B., van Breugel, K., de Vries, J., and Soen, H. “Mix Optimization forConcreteBridgein View of Reduction of Risk of Cracking at Early Ages” Proceedings of the 13th FIP Congress.

[16] Nawa, T., Horita T., “ Autogenous Shrinkage of High-Performance Concrete” Proc. of the Int. Workshop on Microstructure and Durability to Predict Service Life of Concrete Structures,Sapparo,Japan, 2004.

[17] Loukili, A., Chopin, D., Khelidj, A., Touzo, L., “A New Approach to Determine Autogenous Shrinkage of Mortar at an Early Age Considering Temperature History” Cement and Concrete Research, 30 (2000) 915-922.

[18] Jensen, O.M., Hansen., P.F., “Influence of temperature on autogenous deformation and relative humidity change in hardening cement paste” Cement and Concrete Research” V 29, 1999, 567-575.

[19] Garcia-Boivin, S., 2001. Retrait au jeune aˆge du be´ton—De´veloppement d’une me´thode expe´rimentale et contribution a` l’analyse physique du retrait endoge`ne, PhD thesis, Etudes et Recherches des LPC, OA 37 (LCPC Publ., Paris, 2001),

[20] Baroghel-Bouny, V., Pierre Mounanga, Khelidj, A., Loukili, A., and Rafaï, N., 2006. Autogenous Deformations of Cement Pastes Part II. W/C Effects, Micro–Macro Correlations, and Threshold Values, Cement and Concrete Research, 36,1, 123-136.

[21] Justness, H., Clemmens, F., Depuydt, P., Van Gemert, D. and Sellevold, E.J., 2000. Correlating The Deviation Point Between External and Total Chemical Shrinkage With the Setting Time and Other Characteristics of Hydrating Cement Paste, Proceedings of the International RILEM Workshop on Shrinkage of Concrete Shrinkage, V. Baroghel-Bouny, P.C. Aitcin(Eds.), Paris, France, RILEM Publ, Cachan, 57– 73.

[22] Vernet, C., 1995. Mécanismes chimiques d’interactions ciment-adjuvants, CTG Spa.Guerville Service Physico-Chimie du Ciment, Janiver,10.