Bekir Yılmaz Pekmezci, Dursun Zafer Şeker, Emre Tavlı

İstanbul Technical University, Faculty of Civil Engineering

Burak Yorulmaz, Egemen Arabacı, Fatih Güler, Mehmet Gökpınar

Ticem Advanced Building Technologies

ABSTRACT

Ultrasonic shear-wave tomography (UST) is a promising technology in detecting voids, stratifications, cracks and other defects in concrete. With this technique, that is gaining popularity, nondestructive testing of concrete elements by scanning with shear waves and building ultrasonic propagation characteristics in 3D graphical formats are possible. In this experimental study, defects intentionally placed in a mold are sealed with concrete cover. Then, the concrete block containing the defects is tested using UST and B, C and D scan sections are obtained. By interpreting the sections, the ability of UST technique to display the defects is examined.

1. INTRODUCTION

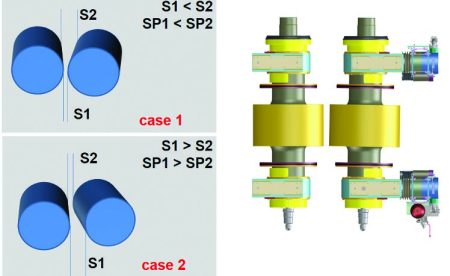

The ultrasonic shear-wave tomography (UST) is a promising technology in detecting voids, stratifications, cracks and other defects in concrete. Nevertheless, UST technique is also used by various researchers to determine the placement and quantity of fittings and layer depths. The ultrasonic shear-wave tomography can be utilized with commercially available shear-wave producing equipment in different sizes [1-4]. The equipment sends out shear waves from its many probes and collects these waves again with its many probes. The number of probes varies depending on the equipment model. The propagation characteristics from a large number of points from the inside the concrete are obtained by collecting the ultrasonic waves, which are sent by probes, from the collecting probes. In tests from a single side, a matrix of the characteristics of all the points on the inside of the concrete mass can be generated and the concrete characteristics of many points in close proximity to each other can be obtained. The data obtained is built as a 3D model with the help of software and sections required can be taken from the model for analysis in terms of concrete defects [1].

There have been many researches and experimental studies on the subject of damage assessment in reinforced concrete elements by utilizing ultrasonic tomography [1-6]. One of the most important collective conclusions from these studies is the easy detection of defects such as cracks, decomposition, delamination, etc., and sections with different concrete characteristics from their surroundings in the reinforced concrete elements by using ultrasonic shear-wave tomography technique [4-6].

It is emphasized that low frequency ultrasonic shear- wave tomography technique can be effectively used to detect defects, which are left or occurred unintentionally during the production process, in up to 2,500 mm depth of reinforced concrete elements such as bridge decks, columns, road concretes and shear walls.

This experimental study contains the conclusions of UST measurements that are conducted both in laboratory and in the field. The equipment used in the experiment has transducers of which some are senders and some are receivers. Each transducer is attached to the equipment with a spring and has mobility up to 8 mm to prevent the surface irregularities from interfering with the measurements. The samples produced are concrete samples in 10x60x60 cm dimensions. The preplanned defects are put inside the mold and sealed with concrete cover. Then, the concrete block containing the defects is tested using UST and B, C and D scan sections are obtained. By interpreting the sections, the ability of UST technique to display the defects is examined. As a defect, expanded polystyrene (EPS) block, gas concrete block and an air-filled plastic bottle are placed inside the concrete. The sizes and coordinates of the defects are noted during the placement.

2. EVALUATING EXPERIMENT CONCLUSIONS

As the sample shown in Graph 1 is prepared, expanded polystyrene (EPS) block, gas concrete block and an air-filled plastic bottle are placed inside the mold to analyze the detectability of the voids in the concrete. The graph shows the B-Scan, D-Scan and C-Scan images. The defects, which are placed in the mold prior to the pouring of concrete, are shown with a mark on the right side of the graph. The scans show that expanded polystyrene (EPS) block, gas concrete block and an air- filled plastic bottle are viewed in nearly the same sizes prior to burying and without any damages. It can also be seen that the placement and the coordinates of the objects, which are buried in the concrete beforehand and represent a defect, are obtainable.

2.1 Evaluating Defects in Terms of Type

All defects consisting of expanded polystyrene (EPS) block, gas concrete block and an air-filled plastic bottle are distinguishable in all B, C, and D scanned sections and in all three planes. However, it is not possible to comment on the defect types from the section images.

2.2 Evaluating Defects in Terms of Dimension

The dimensions of all the defects, which consist of expanded polystyrene (EPS) block, gas concrete block and an air-filled plastic bottle, obtained from the sections are very close to the actual dimension of the defects placed in the sample.

2.3 Evaluating Defects in Terms of Position

The positions of all the defects, which consist of expanded polystyrene (EPS) block, gas concrete block and an air-filled plastic bottle, are determined correctly at the coordinates which are noted during the placement of the actual defects in the mold prior to production.

4. CONCLUSIONS

According to literature search, defect detection with UST technique is a method that can be applied directly to the buildings. In the previous scientific studies it is stated that in laboratories and in the field, this technique can determine defects in measurements very close to the dimensions of the actual defects in concrete. This technique can be used on damaged bridges, viaducts and especially on buildings at the end of their useful life to nondestructively determine the depth and scope of the damage. The UST technique can also be used to take precautions on the ongoing constructions by determining placement and void problems caused by application deficiencies and foreign objects mixed in the concrete.

In the experimental study, all defects consisting of expanded polystyrene (EPS) block, gas concrete block and an air-filled plastic bottle are tried to be detected with the help of SUT sections. According to the experimental study conclusions:

All defects placed in the sample are detected in all UST sections.

No distinguishing data is obtained in terms of defect type

The dimensions of the defects obtained are very close to the real dimension of the defects buried in the sample.

The positions of the defects are obtained as the exact positions of the defects buried in the sample.

Sources 1. Clayton, D., Smith, C., Nelson, J., Khazanovich, L., Hoegh, K., Chintakunta, S., Popovics, J., Choi, H., Ham, S., Evaluation of Ultrasonic Techniques on Concrete Structures, OAK Ridge National Laboratory, ORNL/TM-2014-430, 2013. 2. Chai, H.K., Momoki, S., Kobayashi, Y., Aggelis, D.G., Shiotani, T, Tomographic Reconstruction for Concrete Using Attenuation of Ult- rasound, NDT&E International, No: 44 pp. 206–215, 2011. 3. Chai, H.K., Aggelis, D.G., Momoki, S., Kobayashi, Y., Shiotani, T., Single-side Access Tomography for Evaluating Interior Defect of Concrete, Construction and Building Materials No: 24, pp. 2411–2418, 2010. 4. Hola,J., Schabowics, K., State-of-the-art Non Destructive Methods for Diagnostic Testing of Building Structures Anticipated Develop- ment Trends, Archives of Civil and Mechanical Engineering, Vol.3, No.3, pp.5-18, 2010 5. Schabowicz K., Hoła J.: Nondestructive elastic-wave tests of foundation slab in office building, 13th Asia-Pacific Conference on Non- Destructive Testing, Yokohama, Japan, 2009. 6. Schabowicz K., Hoła J., Styś D.: Nondestructive elastic-wave tests of concrete in foundation slab, 10th European Conference on Nondest- ructive Testing, Moscow, Russia, 2010.